We love technology – and have done since 1919! In 2019, LÄPPLE Group celebrated the 100th anniversary of its founding. A good time not only to look back, but also forward into the future.

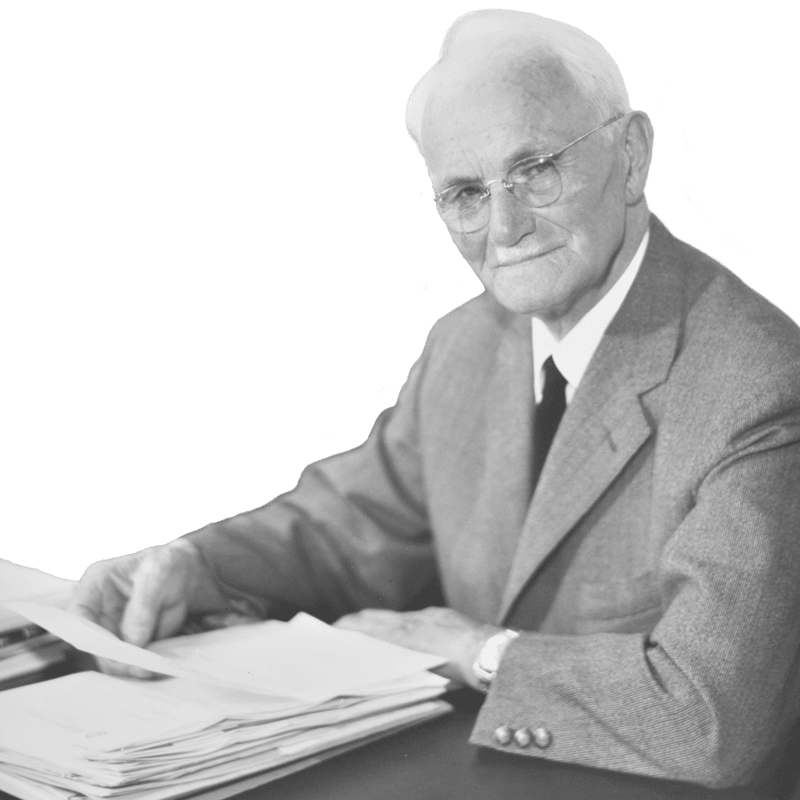

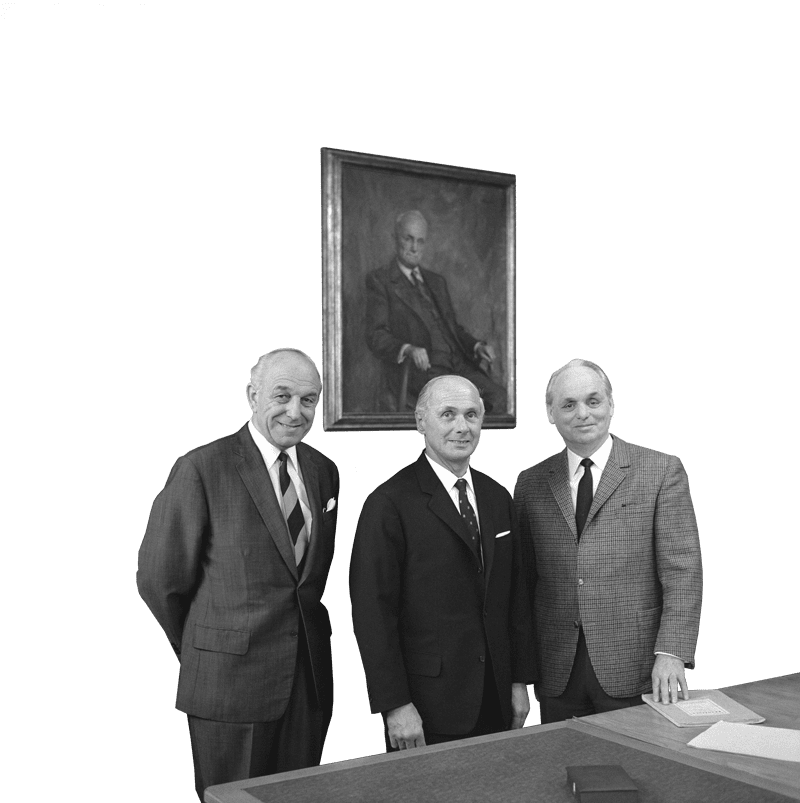

In 2019, we celebrated the know-how, the courage and the commitment of all employees who have supported LÄPPLE over the last 100 years – and, of course, our founder, August Läpple, whose expertise, versatility, adaptability and passion made the company what it is today. These are factors which continue to characterise LÄPPLE Group and which have become part of our corporate culture.

MAXIMUM PRECISION SINCE 100 YEARS

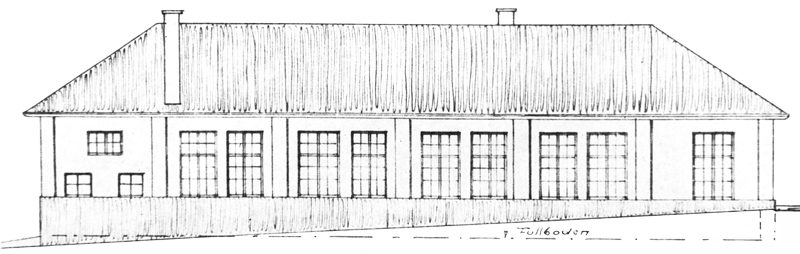

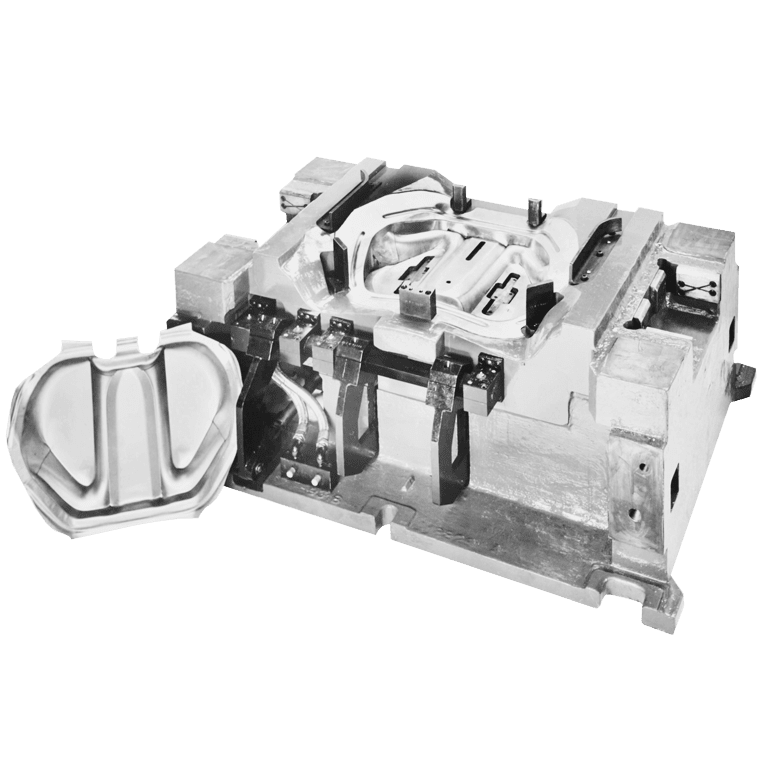

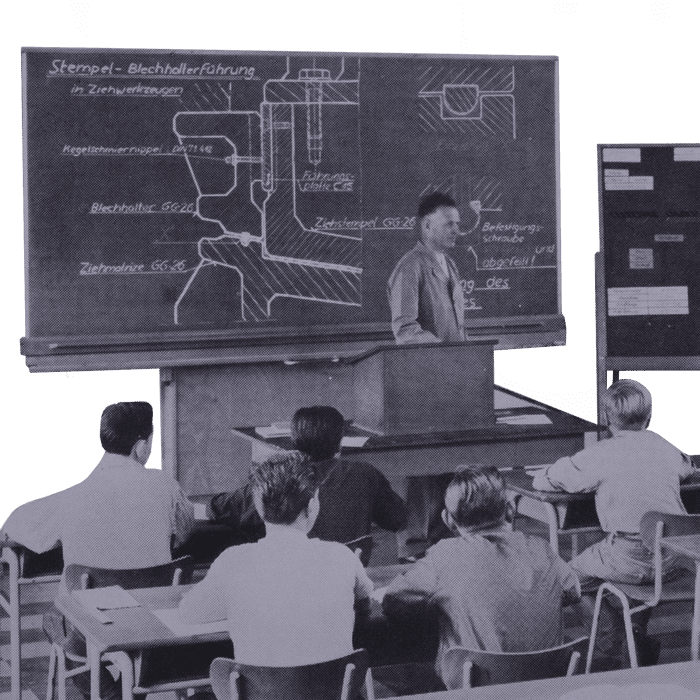

Our anniversary motto expresses what has distinguished our company over the last century – and continues to distinguish us to this day. Maximum precision. Following the foundation of the company in 1919, August Läpple, a toolmaker with great passion for his trade, put his considerable skill to work, and the high precision of his products soon earned him a reputation within the region. He continually increased his expertise in accordance with his credo “If you don’t go forwards, you’re moving backwards” and, as a technological trailblazer, always maintained exceptionally high quality standards.

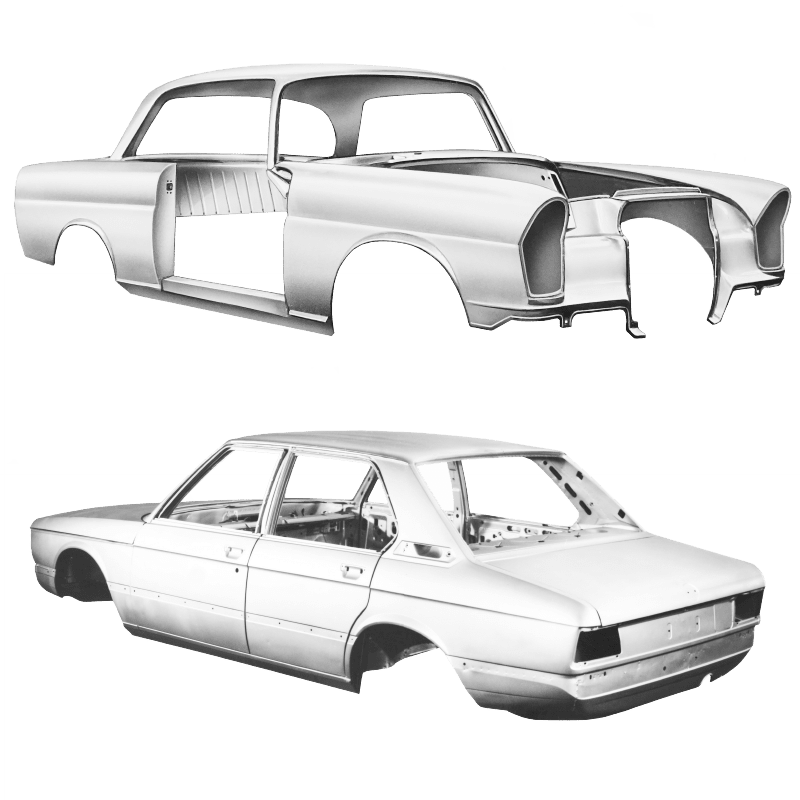

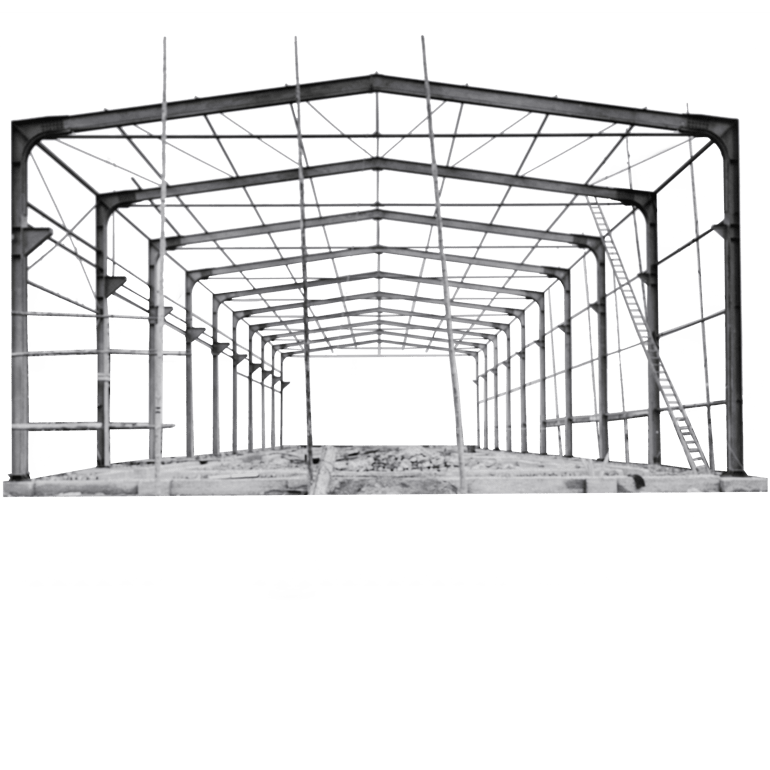

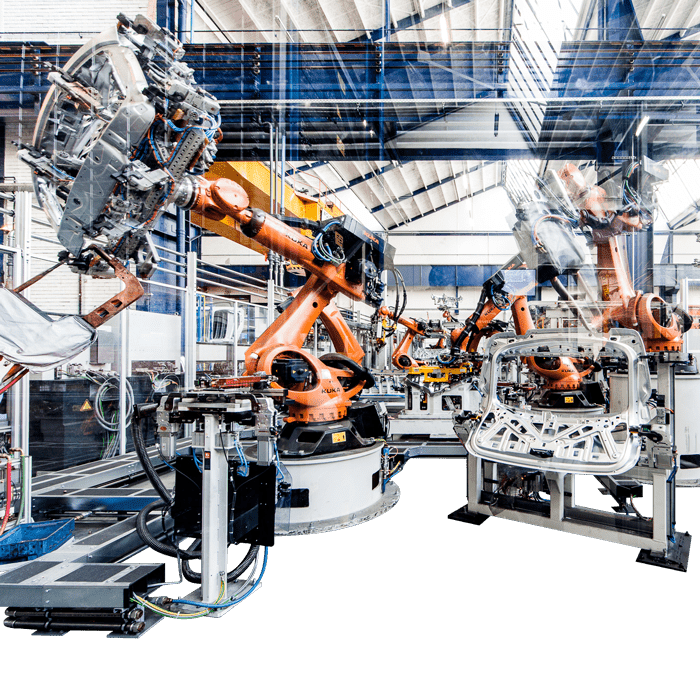

The term “precision” continues to be an apt description of what we demand of all our products, processes, services and of ourselves in our day-to-day work. Precision as the criterion for evaluating quality is exactly what distinguishes LÄPPLE AUTOMOTIVE, FIBRO, FLT and our training company in all fields of activity. The precisely manufactured sheet metal parts, the development of high-precision standard parts, rotary tables which optimise our customers’ production lines through high-accuracy positioning, precise interlinking in system engineering in order to map the requirements, cycle times and processes of our customers or the targeted training of the skilled workers of the future.