FOUNDING A WORKSHOP

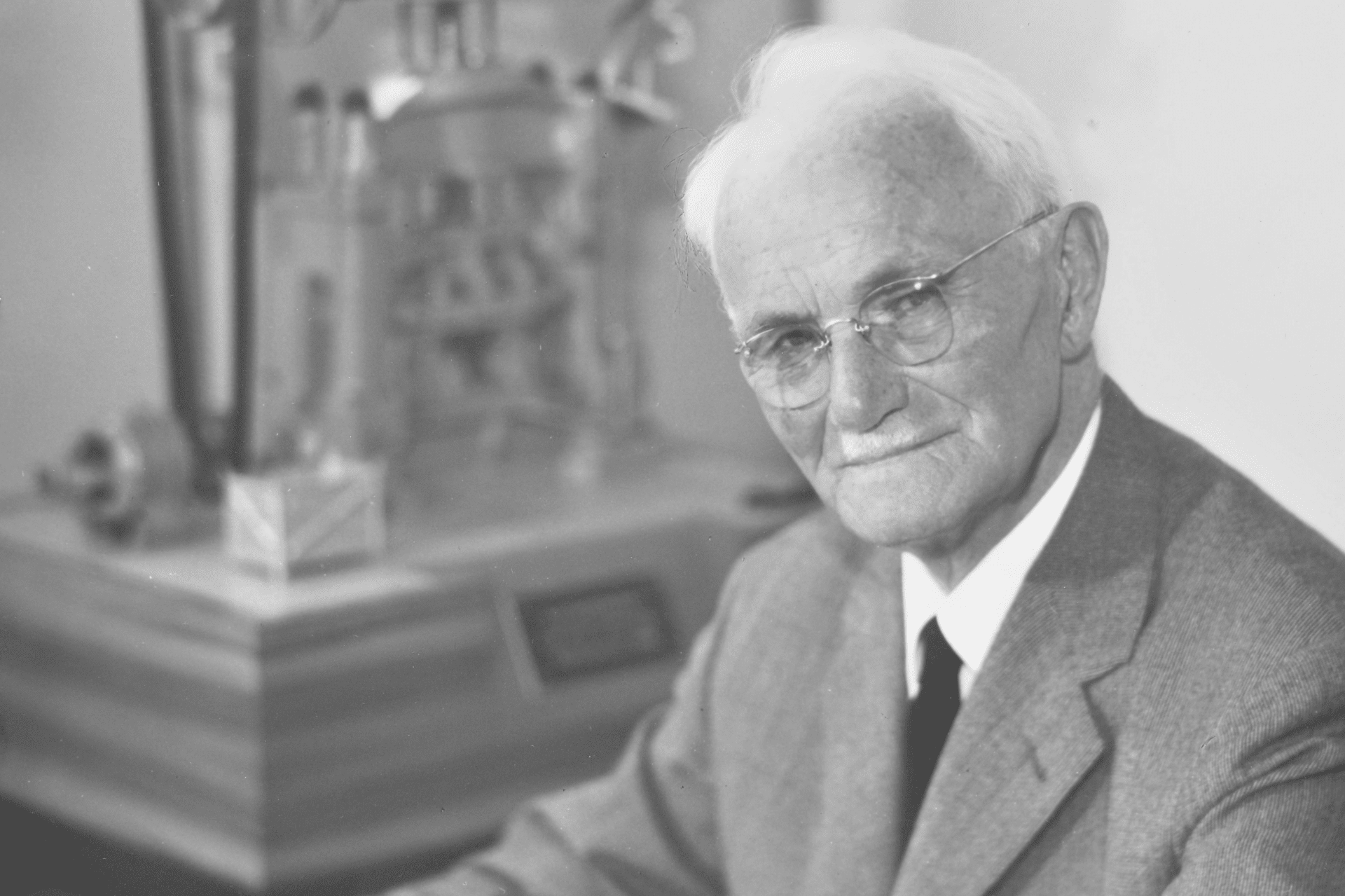

On 1 April 1919, August Läpple (1885–1968) founded a small mechanical workshop in Weinsberg complete with a smithery. His first jobs were to repair bicycles and agricultural machinery, as well as manufacture cutterbars for mowing machines.

FIRST MAJOR PROJECTS FOR THE AUTOMOTIVE INDUSTRY

After growing the company’s manufacturing portfolio, it started doing business in the field of tool construction for various industries, notching up its first major projects for the automotive sector in 1928.

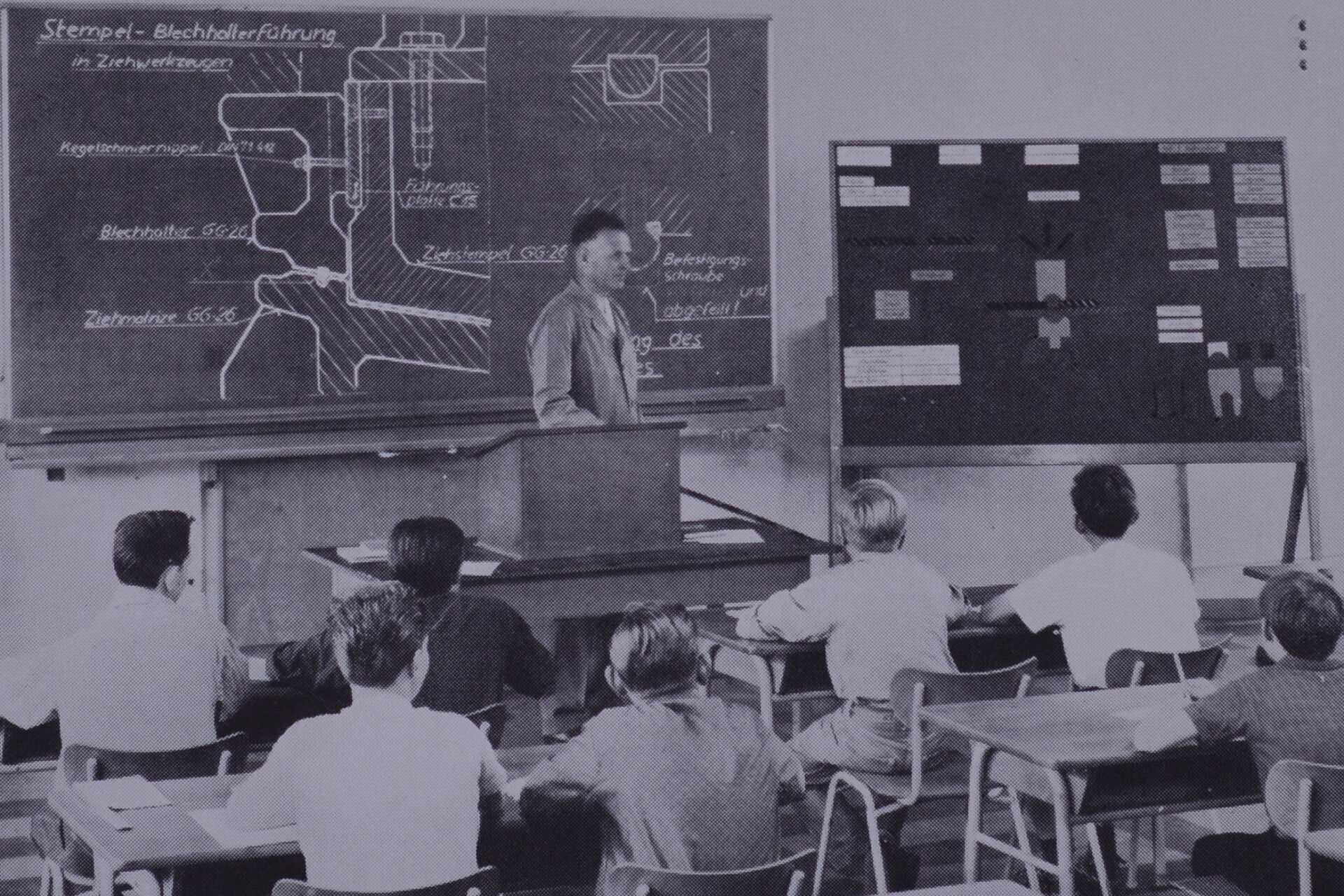

FOUNDING OF THE LÄPPLE APPRENTICE SCHOOL

Having a good training background and useful qualifications was incredibly important to the entrepreneur. That’s why, in 1930, he set up a separate apprentice school, laying the foundations for what would become LÄPPLE’s current training and professi

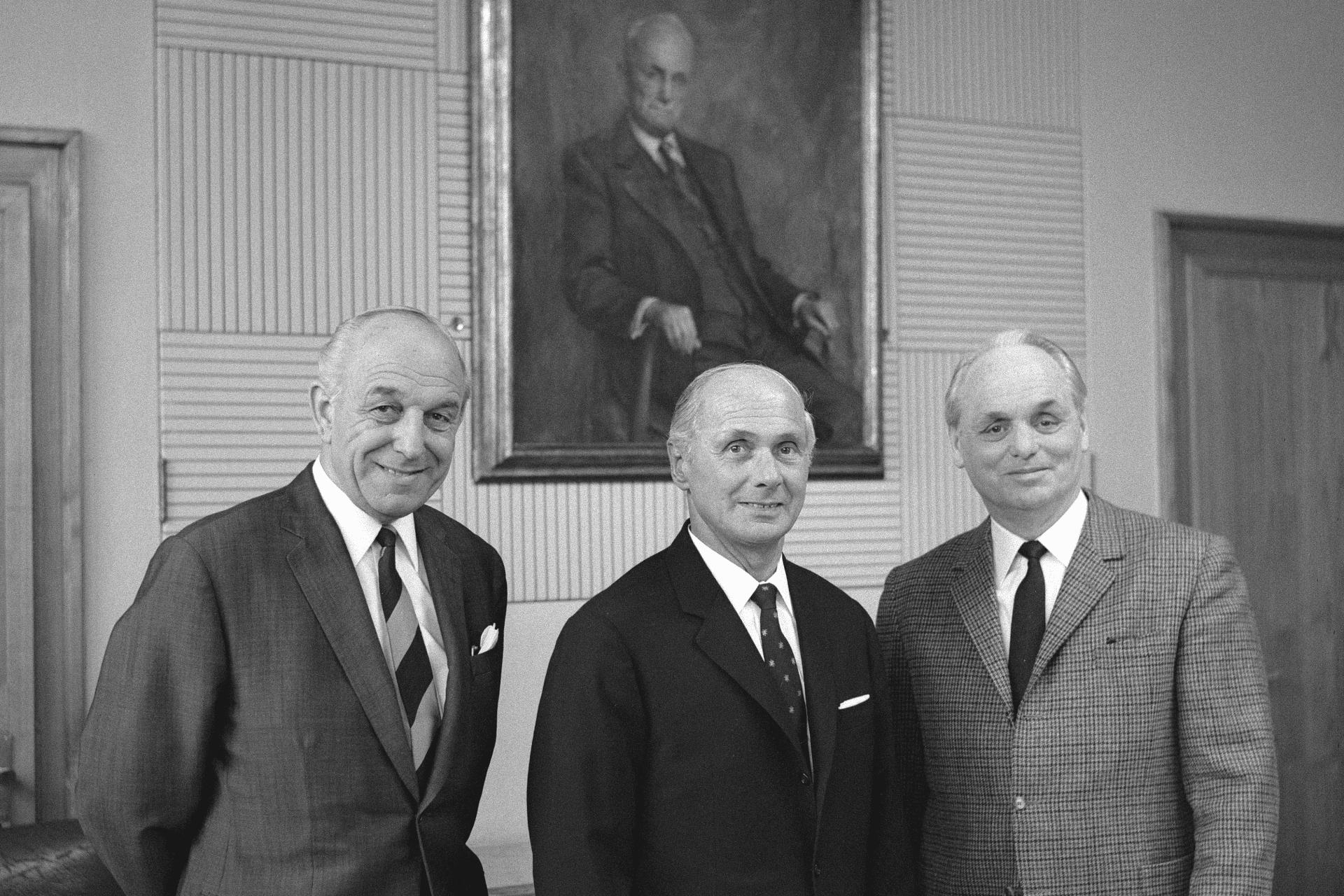

TAKEOVER BY THE SECOND GENERATION

August Läpple stepped down from active leadership of the business. Subsequently, his sons Erich and Helmut Läpple, as well as his son-in-law Ernst Fleischmann, assumed leadership of the company.

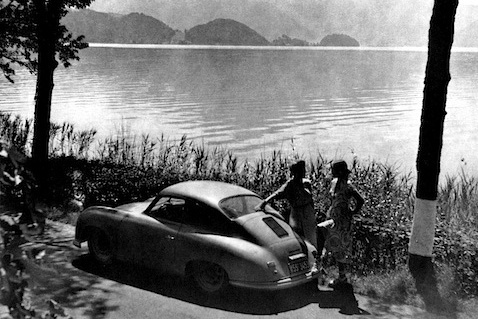

LÄPPLE BECOMES PORSCHE’S PRIMARY SUPPLIER

When the German car industry was deregulated following the country’s 1948 currency reform, the company’s order book grew significantly. The company became the primary supplier of the Stuttgart-based carmaker Porsche, which remains a customer to this d

RELOCATION TO THE NEW SITE IN HEILBRONN

In a bid to overcome a chronic lack of space, which was only getting worse, LÄPPLE relocated all of its operations to Heilbronn in 1950. A new factory was built on Austraße, where the headquarters of LÄPPLE AG remain to this day.

LÄPPLE BECOMES THE LARGEST INDEPENDENT TOOLMAKER IN GERMANY

By manufacturing large tools for use in bodywork construction, motorcycles, helmets and refrigerators, as well as a wide variety of small tools, the company grew massively in the 1950s, employing over 1300 workers.

COMPANY FOUNDER AUGUST LÄPPLE DIES

Company founder August Läpple passed away on 6 November 1968 at the age of 83.

STANDARD PARTS AND ROTARY TABLES ADDED TO THE COMPANY’S PORTFOLIO

LÄPPLE acquired FIBRO GmbH, a manufacturer of standard parts and rotary tables with sites in Weinsberg and Hassmersheim.

NEW SITE ESTABLISHED IN TEUBLITZ

Three years after the closure of the Maxhütte-Haidhof steelworks, LÄPPLE acquired the 400,000 m² site for its sheet-metal working division. Following conversion and renovation work, production began in the new factory in May 1991.

FOUNDING OF LÄPPLE AG

By the end of 2000, the Läpple family had stepped down from active leadership of the business. The company was then renamed as an Aktiengesellschaft – a public limited company. To this day, the family holds 100% of shares.

GROWTH OF THE COMPANY’S AUTOMATION PORTFOLIO

The company GSA Automation was acquired and integrated into FIBRO in efforts to grow the Group’s robotics and automation portfolio.

EXPANSION INTO INDIA

Following the founding of FIBRO India, a new production site was erected in Pune.

CONSOLIDATION OF AUTOMATION KNOW-HOW

The newly renamed FIBRO LÄPPLE TECHNOLOGY GmbH (formerly FIBRO-GSA and LÄPPLE Anlagenbau) was to become a hub for the Group’s automation expertise.

ADDITION TO THE HEILBRONN PLANT

In light of the company’s growing order book, a new bodyshell manufacturing division over 3500 m² in size was built at the Heilbronn factory.

EXPANSION INTO THE ASIAN MARKET

Internationalisation on the Asian market was explored further with the founding of FIBRO Korea Co. Ltd and FIBRO (Shanghai) Standard Parts Co., Ltd China.

ADDITION TO THE HEILBRONN PLANT

A new 2500-tonne transfer press, complete with ServoDirect technology, was built at the Heilbronn site. The press added to the company’s XL press portfolio and made it possible to manufacture complex structural components from steel and aluminium.

INVESTMENTS IN INFRASTRUCTURE

The largest project in the company’s history involves the construction of a 5000 m² building which, as of 2018, will be used for manufacturing vehicle components, incorporating seven different production lines and cells with nearly 60 robots.

EXPANSION OF PRODUCTION IN INDIA

A second plant is established in Pune to expand FIBRO's productive capacities for standard parts and rotary tables.

FOUNDING OF LÄPPLE TAICANG

With the foundation of LÄPPLE Taicang, the efforts of all LÄPPLE companies in China are bundled. The operative business as well as the production can now take place close to the customer. The sales activities of FIBRO and FLT are still separated.